Products for efficient, safe and environmentally conscious handling of HFCs, PFCs and hydrocarbon refrigerants

Generation I

Specially designed for split air conditioners and heat pumps, repeated coupling and decoupling of the stop valves is expected only sporadically.

HFC, PFC; NPS 1/4″ to 5/8″

Generation II

Companion valves for use in supermarket refrigeration units, refrigeration and beverage vending machines, and smaller refrigeration systems using HFC and PFC refrigerants.

HFC, PFC; NPS 1/4″ to 1/2″

Generation III

Companion valves for use in supermarket refrigeration units, refrigeration and beverage vending machines, and smaller refrigeration systems using Hydrocarbon refrigerants.

Hydrocarbon; NPS 1/4″ to 1/2″

Generation IV

The latest generation has been developed for universal use in refrigeration, air conditioning and heat pump technology up to NPS 3/4″ and for a wide range of connection options.

Self-closing companion valves

Ensuring modular applications and Plug-and-Cool solutions in refrigeration and air conditioning

Self-closing companion valves for continuous use for liquid and gas transfer

Repeated coupling and decoupling without evacuation / refilling of components without lengthy interruptions to the functions of the refrigerant and air conditioning systems

Advantages and benefits

Possibility of evacuating and/or pre-filling of components and pipes/hoses

Reduction of effort in case of guarantee or warranty or at the replacement of components

Industrially manufactured connections rule out errors. during assembly and guarantee high reliability and minimal leakage rates.

Saving of time and technical equipment at installations of new facilities as well as at the maintenance

Use at any point in the refrigeration circuit enables. Components to be changed quickly and easily without any technical effort and without releasing refrigerant.

Possibility of a simple and timesaving change of location without expensive equipment and at minimized refrigeration losses.

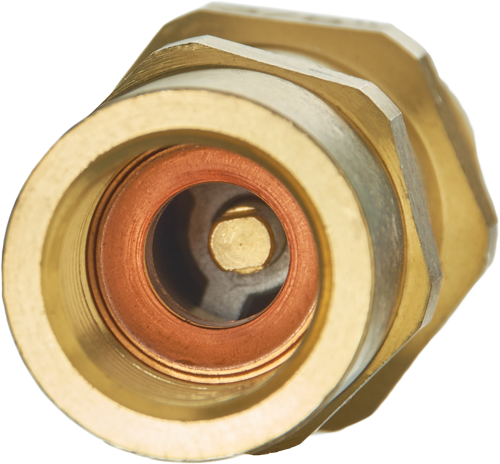

All factory made 45° SAE flared fittings are factory fitted with captive conical copper O-rings. Due to the cactory production, the copper sealing rings and the application of the tightening torques according to EN 378-2:2018-04, a high level of tightness of the connections is reliably achieved.

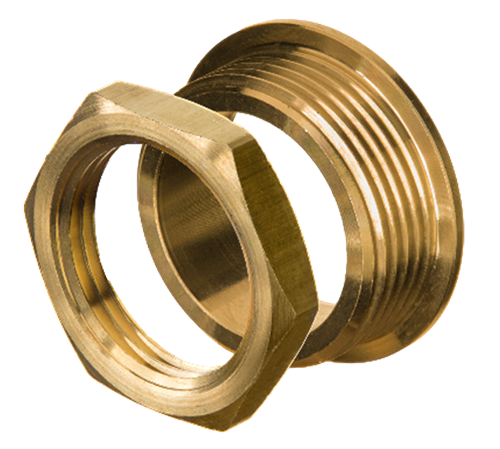

The male stop valves of generation II, III and IV can be factory fitted with a mounting ring. This means that these stop valves can be mounted firmly in a (housing) wall.

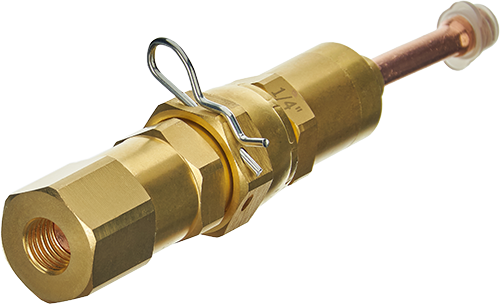

Generations II, III and IV and also the improved Generation I, which was launched in 2022, are supplied with locking pins made of stainless spring steel as standard. If these pins are used, hand-tight screwing of the mating stop valves is sufficient when coupling. Damage to the threads due to improper assembly is therefore excluded.

As an option, the female stop valves can be supplied with a decoupling protection that meets the relevant European standards for hermetically sealed systems, requiring special tools for removal.